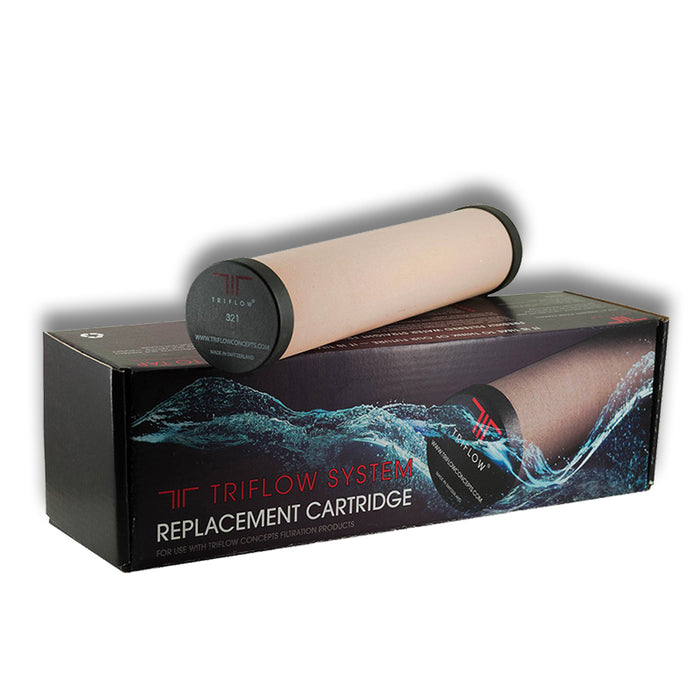

Triflow TF321 Genuine & Original Manufacturers Replacement Water Filter Cartridge

The Katadyn Inc. TF321 is the original manufacturers product and has been made in Switzerland specifically for the Triflow/Franke Triflow and more recently Perrin & Rowe system for over 25 years.

The Katadyn filter has been the Manufacturers chosen filter since the Triflow system was created in 1992, it is still the recommended filter up to the modern day.

So there is NO confusion, the product code for this filter has changed over the years, it was formerly, for many years the FRX02, then FR945 and today TF321, do not be mislead with other filters on the market, irespective of where they are coming from which have the same or similar code numbers, the Genuine Katadyn Inc. product has a pink coloured ceramic unlike other compatible products on the market that are white ceramic.

Specification:-

l Manufactured from survival grade materials

l Removes 99.999999% of bacterial pathogens

l Silver impregnated to stop bacteria growth

l Active carbon improves taste and odour

l Reduces heavy metals inc. Lead

l Each filter is individually quality checked

l Previously named FR9455 or FRX02

Product Data for the TF321 Cartridge

The Triflow TF321 cartridge embodies Katadyn’s manufacturing and water treatment technology to provide the optimum combination for good tasting, healthy water. This universal cartridge is provided as the basis for the range of Triflow water treatment systems. Alternatives are available, however, for special requirements or installations.

It has four key elements:

- Katadyn Ceramic micro-filtration

- Bacteriostatic silver

- Carbon block matrix

- Zeolite - ion exchange

Katadyn inside

The outer shell of the TF321 cartridge is a high quality, micro-porous ceramic media which traps out, not only silt and debris, but pathogenic bacteria and protozoan cysts. The ceramic is manufactured at Katadyn’s modern factory in Wallisellen, Switzerland, where carefully selected raw materials are subjected to a precisely controlled manufacturing process to produce the high quality ceramic filter media. Katadyn’s experience in this field of technology is second to none. They have been involved with water treatment since 1928 and their products, as befits the Swiss reputation, are renowned for their consistency and reliability. There are many manufacturers of ceramic water filters around the world but few, if any, manufacture to the same fine-pore-structure consistency and exacting levels of quality control. When dealing with pathogenic microorganisms, quality is paramount and only the best will do!

Bacteriostatic Silver

Katadyn’s ceramic is impregnated with silver during the manufacturing process. Silver is a bactericide. It has been known for centuries that silver is an appropriate material for water containers. The Romans used to store their drinking water in silver vessels. It is only over the last hundred years or so that the microbiology of water has been understood and that the efectiveness of disinfectants has been assessed. The bactericidal action of silver is called the “oligodynamic” efect from the Greek “oligos” meaning small and “dynamis” meaning action. In fact Katadyn’s name was derived from the German word Katalytisch, meaning catalytic and oligodynamic. The silver ions released from the ceramic in very low concentrations attack the DNA and enzymes in the bacteria which prevents their reproduction.When added to the ceramic, the silver acts bacteriostatically, that is it inhibits the growth of bacteria in the ceramic.

Carbon Block

The activated carbon, within the core of the Katadyn ceramic, is manufactured by extruding a mixture of granular activated carbon and polyethylene powder at an elevated temperature so that the activated carbon particles bind together to form a tight matrix. The carbon block manufacturing process is precisely controlled to ensure that the pore structure is consistent so that water flows uniformly through it. The bituminous coal based activated carbon used is carefully selected and graded to give the optimum adsorption properties for domestic applications. Water passes through the ceramic wall and then through the carbon block. As it does, organic contaminants in the water diffuse into the structure of the carbon granules and are adsorbed. Chlorine is also effectively removed but by conversion to the chloride ion by reaction at the carbon surface. The TF321 is sized so that it will treat a normal domestic drinking water application for at least six months.

Zeolite

A pulverised synthetic zeolite or inorganic cation exchange material is intermixed with the activated carbon prior to its extrusion. The zeolite has the capability to remove heavy metals with a high specificity for lead.

Conclusion

Thus the composite TF321 cartridge has the capability in one small unit, to remove the following:-

Pathogenic bacteria

Cysts

Turbidity

Chlorine

Organics

Heavy metals

Taste

Odour

Colour

And it leaves the essential minerals, such as calcium and magnesium, unaffected.